Most of our clients receive notices from vendors when leadtime changes significantly. Sometimes these notices are at the product level, for example when a SKU is on extended backorder. Occasionally, a notice may impact many items, such as when a manufacturing facility is temporarily shut down.

The COVID pandemic is causing more frequent supply chain disruptions, leading to an increase in leadtime updates from vendors. Hydrian has been getting a lot of questions about how to respond, particularly when it comes to updating leadtimes within an ERP or purchasing system. In this short article, we will provide some pointers on how to use leadtime updates to improve customer service while avoiding unnecessary excess stock.

Determine the type of leadtime change

The most important question to answer before taking any action in response to a leadtime update is: how long will the new leadtime be in effect? There are generally two possibilities here:

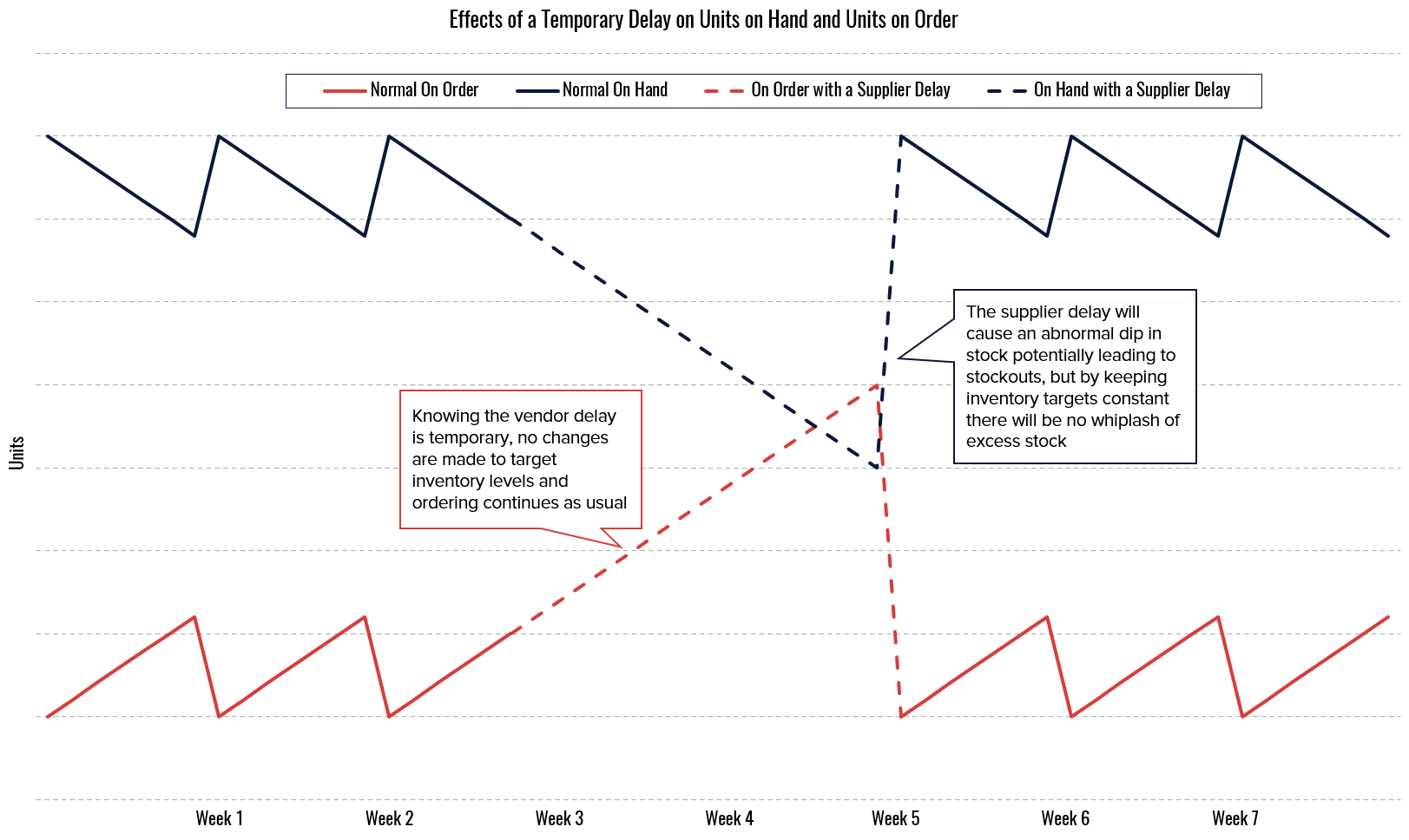

- The first and most common situation is that the new leadtime is due to a temporary delay, such as when a needed component is backordered, or a facility is shut down for cleaning. In this situation, once the backorder is resolved or the facility is back online, all open orders can be fulfilled and will ship simultaneously. We refer to these leadtime delays as shark fins.

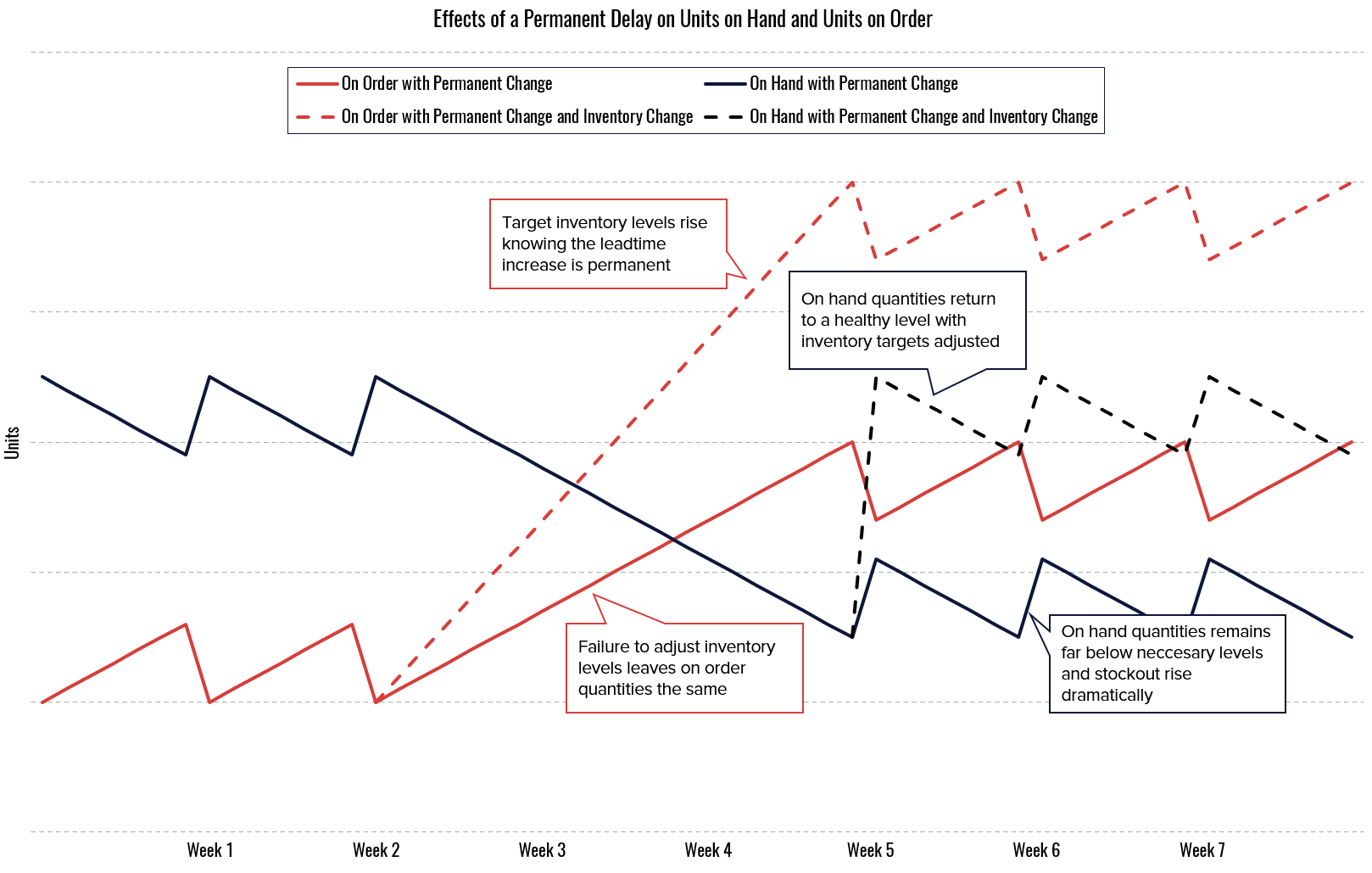

- Alternatively, the new leadtime may represent a long-term change. For example, a vendor may be shipping product from a new facility that is further from your warehouse. In that case, leadtimes will likely never return to their prior level. We refer to this leadtime changes as plateaus.

When to act on a leadtime update

Many systems automatically update leadtimes based on recent receipt history, which is generally a good thing. However, depending on the type of leadtime change that has occurred, it’s important to ensure that the leadtime in the ERP or purchasing system is reflective of what future leadtimes will actually look like.

In the first scenario, there is nothing that can be done to avoid stockouts – ordering more product will only cause an even larger receipt to arrive once the disruption is over, exactly when the extra inventory is no longer needed. In this case, the vendor’s leadtime update should be used solely as a service tool, to communicate with customers about when they can expect delivery. Receipts impacted by the temporarily increased leadtime will need to be excluded from the system’s calculation, or leadtimes will need to be manually adjusted downward so that inventory targets are not increased in error. This is illustrated in the chart below.

In the second scenario, leadtimes must be adjusted upward in the ERP or purchasing system, so that inventory targets can be increased appropriately. This will likely need to be done manually, to reflect the new reality and override the older, shorter leadtime history. The goal here is to get the system to increase the amount of product on-order at any given time, so that high service levels can be maintained despite the longer transit time to your facility. This is illustrated in the chart below.